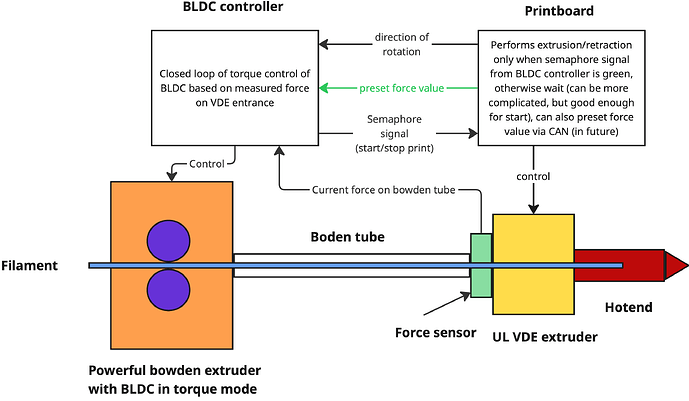

I am thinking about this setup. On the side of printhead we have very light VDE-100 extruder (extruder A) with weak nema-14 pancake, (all together, extruder + stepper, is like 50 grams or less). This pancake does not enough of torque to extrude, but construction of VDE is good enough to act as filament gate with controllable pass through, if we have force from somewhere else. On other side of the Bowden tube (on the frame) we have powerful extruder B (doesn’t matter which one, as weight is not an issue there). Where bowden tube connects to the extruder A, we have force measurement point where we measure force in the bowden tube with force sensing resistor, for example. So, effectively, extruder B provides us with force, and extruder A acts like controllable gate. Then extrusion works like this:

we want to extrude, we control extruder B to push enough, that force will reach some target value (so, we preloaded extruder A), then by extruder A we actually extrude (in reality, it does not extrude but allow given amount of filament to path, with force provided by B), at the same time we still control force to be at target value by pushing filament by B. Once we stop, we can gradually/immediately release force, or keep system, preloaded. When we need to retract, we reverse stepper B, and pull filament till we reach target retract force value, then we “retract” by stepper A (while pull by B still maintains target force). So, in this system extruder A is kind of main extruder, which is responsible for accuracy, but force is provided by extruder B, which can be as heavy as we want.

So, how complex this will be to implement?

In some sense, it is bowden pressure advance system, but

-

with exact measurement of force/presure in the bowden tube on the hotend side (or both sides, it might have some value).

-

with controllable gate on hotend.