This wasn’t the way to do it.

Is SPI clocking in Klipper documented anywhere? I’m asking because the documentation for the ADXL345 says that the default datarate is 5Mbps: Configuration reference - Klipper documentation

I guess if a bit-banging SPI interface was selected, then any arbitrary datarate (up to a given speed) could be specified, but what happens with using the built in SPI port?

Let’s just focus on the Manta PCBs because that’s what I’m working with here.

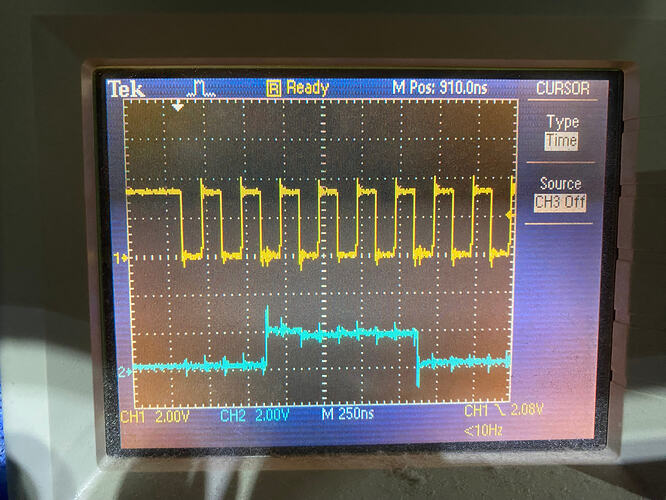

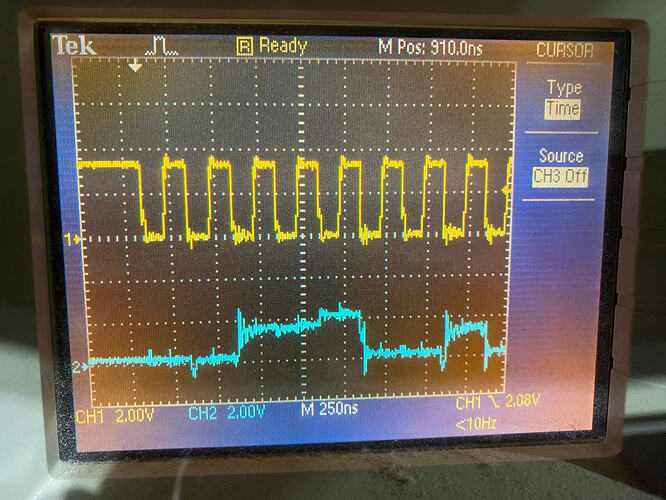

Now, I’ve just gone through all the schematics and your schematic snippet above for the level shifter implementation isn’t correct for SPI lines on the Manta M4P/M5P/M8P V1 boards (it appears to be the signals on the STEP pins and they’re pretty ugly waveforms). I’ll comment on Manta M8P V2 below.

When I look through the schematics for the selected boards, the SPI SCK and MOSI lines fan out to the steppers and the SD Card socket and the general purpose SPI connector. The lines going to the stepper drivers are redriven through CMOS buffers which raise their logic levels to 5V so there really isn’t anything controversial there.

The issue is when I look at the MISO lines on the selected boards. Going through the schematics, they all can be drawn out as:

I haven’t included the decoupling caps on the pull up resistors which may or may not be a factor in the line’s operation and I haven’t put the TVS diode on the 3.3V MISO line. Note that the Manta M8P only has one 10k pullup on the 3.3V MISO line while there are two on the other boards.

Regarding the Manta M8P V2, it has three SPI buses - one for the stepper motors, one for the SD Card slot and one for external devices. This is what I would consider the correct way to implement the SPI connections and should minimize/eliminate the issues I’m seeing here.

Going back to the other boards, MISO is held high unless one of the devices on either the 3.3V or 5V MISO lines are pulled low. There shouldn’t be a problem for the devices on the 3.3V MISO line (the SPI Connector ro the LCD Connector). But, for the stepper MISO lines, there are the pullups along with the capacitance of the line to the SPI Connector. This also includes the capacitance of the diode (which, for the IN5819W used on the Manta boards, is surprisingly high).

I suspect that if I were to look at the MISO signals provided by the stepper motors at the MCU using an oscilloscope, I would see a pretty distorted signal with the 2.2m long ADXL345 cable in place versus the 25cm cable where things work which would have a more reasonable signal.

So where do I go from here? If I really cared, I’d scope out the lines to see if my hypothesis that the MISO signals on the 3.3V line from the stepper drivers is distorted with the long ADXL345 cable and then cut down the cable to see if that improves the MISO signals and what is the maximum length cable that things work at.

However, I don’t really care. The object of this exercise was to get the TMC2240 stepper motor drivers working with SPI in my printer. I can get the ADXL345 connected to the rPi CM4 GPIO bus so I can have that feature available to me. Now, if this is information that is useful and important to somebody, please let me know and we can talk.

Otherwise, I’m satisfied that my questions have been answered on this issue.