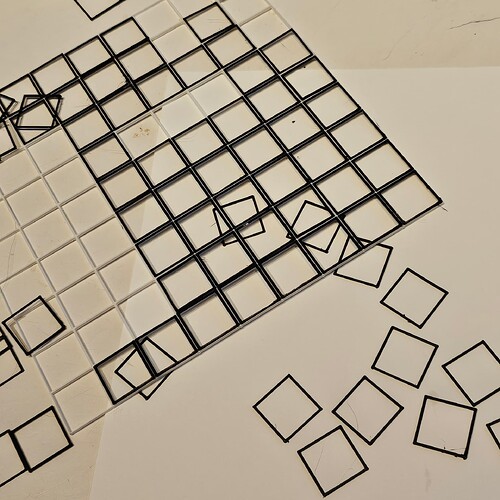

Remember the CD coaster days? I’m in some “margarita glass drying rack” days, making a lot of margarita glass drying racks.

It’s one step up but I’m almost at my wits end.

I have not been able to improve the 0.5 mm radius corner.

I have adjusted the pressure advance and corner velocities across a large range, and have yet to make any improvements.

I have also been unable to make improvements in the tuning tower.

I followed this up by grepping the klipper-master directory for terms like “nozzle,” “corner,” “radius,” “minimum,” and yeah, “‘0\.5\ mm’”

I have made at least one hundred Margarita Glass Drying Racks prior, now I may be selling these on Etsy soon because they continue to multiply.

That aside, does anyone know if I could make any improvements on the corner radius using Klipper. I know that I do not know what I’m doing, entirely.

But I had run the aforementioned tests, with the aforementioned results.

I do not believe that I need to use a laser beam to make cuts into some material to exceed the 0.5 mm corner radius, right? Klipper can do this. Right??

Besides, there are other surfaces that I am working with that can not be cut, but on the contrary can be easily constructed using a 3D printer (this is not a problem, but an advantage) … provided I can improve this radius.

[The rails are 0.25 mm wide, and the corner radius is consistently 0.5 mm. So maybe the corner radius is determined by a factor of two, somewhere. Things just got weird. Maybe I just need to make more changes to the corner velocity and pressure advance, IDK.]

I just need to make this “tiny” improvement (a factor of two). Pun intended.

I will be attempting to use 0,1 mm nozzle next, if required. But I would like to read if anyone else has any ideas.

Thank you so much for your replies!

If anyone can, please let me know if there is any weird corner/factor defaults in Klipper, basically.

I didn’t find anything in the impossible to find klipper-master files yet. They are amazing files!