Well, I think there is basically no difference between LAN and the Internet.

The basic difference is that one is Local and the other is a global network.

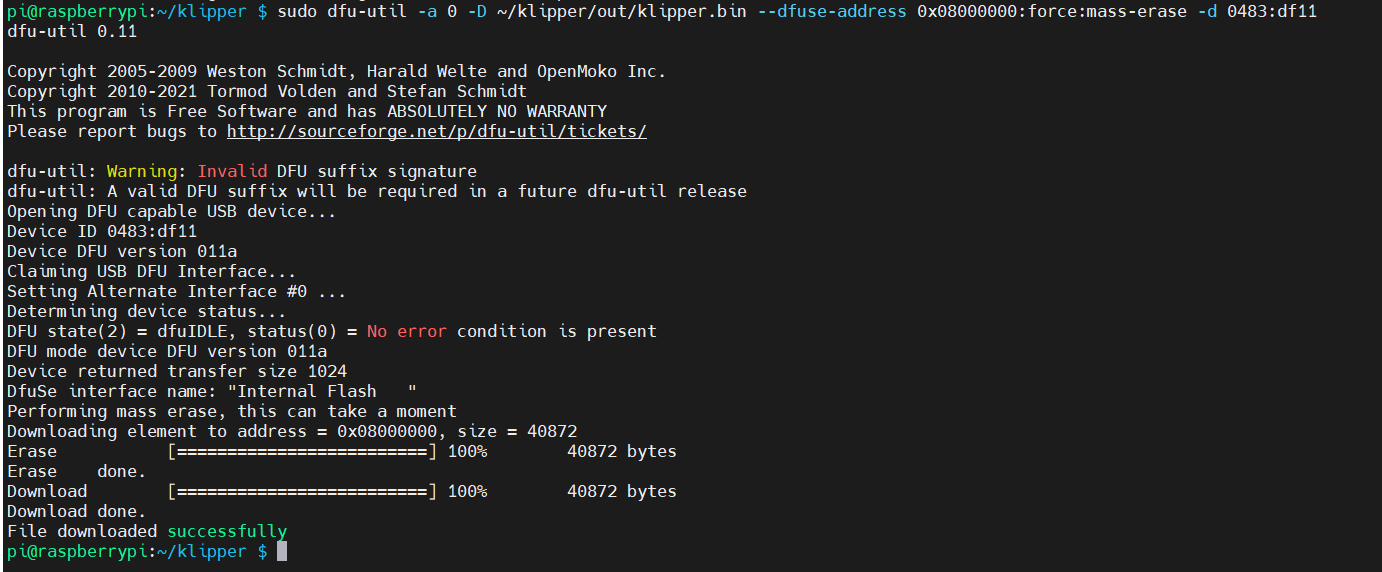

Klipper could listen local socket. Klipper provides JSON RPC, which is not HTTP.

So strictly speaking, it is not a web server (a web server generally should serve HTTP content: World Wide Web - Wikipedia).

Moonraker, on the other hand, is the Web Server. It serves HTTP on some TCP port.

Probably there is also an Nginx (Proxy and Web Server) that is proxying the Moonraker and serves the WebUI/Client files to the browser (client - you). So, the browser could execute them, show you UI of your choice, which underneath would send requests to the moonraker.

Generally speaking, you can run any of those things locally (within your network).

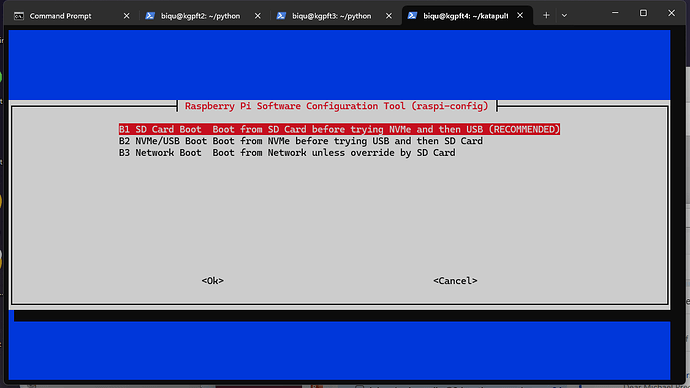

Well, this is why you install everything on the SBC.

So, you locally (in your network) access the Nginx on the SBC.

It serves you the WebClient.

WebClient, through the nginx, accesses the Moonraker, which accesses the Klipper.

(This is what Kiauh does by default).

Could you run the stack without internet access? Definitely.

Could you run it with internet access? Definitely.

Could it access the internet? If your LAN has internet, it probably could do that.

Could you access this from the internet? If you publish it to the internet, you probably can.

Could you run it on “localhost”? You can.

Localhost means 127.0.0.1, literally localhost.

My host has 127.0.0.1, your host have it, any device with network stack would have it.

It meant to work with things locally.

Think about it as a sort of “self”.

Can I access myself? Probably yes.

Can somebody access my “self”? Probably no.

Hope that explains something.