Basic Information:

Printer Model: N/A

MCU / Printerboard: Discussed Below

Host / SBC: N/A

klippy.log: N/A

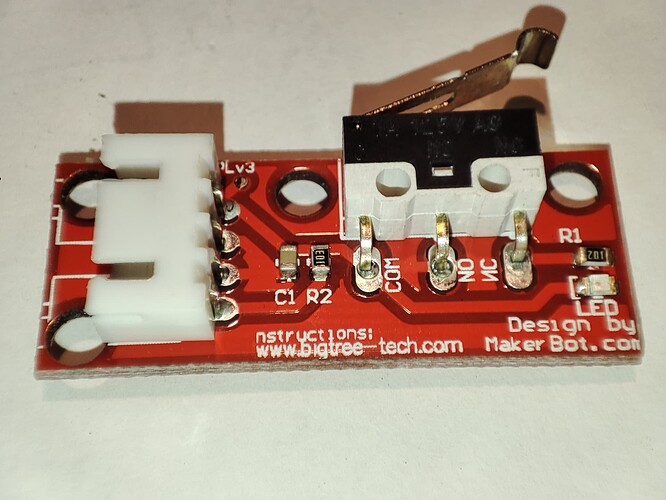

I was looking at some main controller board schematics and I noticed that for endstops, the basic circuit consists of a 10k pullup with a 0.1μF cap like what you see in the Manta M8P:

I looked at a number of different 32bit controller board schematics and they all have this basic circuit with the only difference being is that some have TVS protection diodes after the 100Ω current limiting resistor. I put in the qualifier “32bit” above as the RAMPs board just has a 10k pull up leading to a 4050 CMOS buffer for input protection.

The reason why I’m asking what Klipper’s homing sampling rate is that the RC time constant of these two values is 1 millisecond which translates to a rise time of 5ms which seems to be fairly high for getting a precise measurement in a moving system.

I did a search in the Klipper documentation but didn’t find anything regarding the homing sampling time.

This shouldn’t be a problem for most people as it would be a non-issue for X/Y homing and the only “modern” Z axis homing approach where I could see this as an issue would be Klicky or using a microswitch on the end of a servo’s output arm.