Basic Information:

Printer Model: custom I3 - IDEX wwith nema23 motors on X1, X2, Z1, Z2 and Y

MCU / Printerboard: BTT Octopus Pro + 2x EB42

Host / SBC: Desktop PC

Hi, I just replaced the old TB6600 stepper drivers of my printer with the ones from the title.

The issue is the following: the Z axis motors, with stealthchop disabled, sound like normal noisy stepper motors. If I enable stealthchop, instead, the motors vibrate and sound like they are shaking the whole machine apart.

-Z, SC ON: Imgur: The magic of the Internet

-Z, SC OFF: Imgur: The magic of the Internet

The X axis motors are very silent during printing, but they “squeal” quite badly when i jog them from the klipperscreen “move” menu, especially the left one (it’s a 76mm motor like the Z ones, so that might be the reason).

The noise on the X axis seems to get better the more it moves, as if there is some kind of autotuning going on.

edit: keep in mind that the X noise is amplified by the aluminium plates holding the EBB CAN boards.

- X right, SC on: https://imgur.com/MuuYDUr

- X left, SC on: Imgur: The magic of the Internet

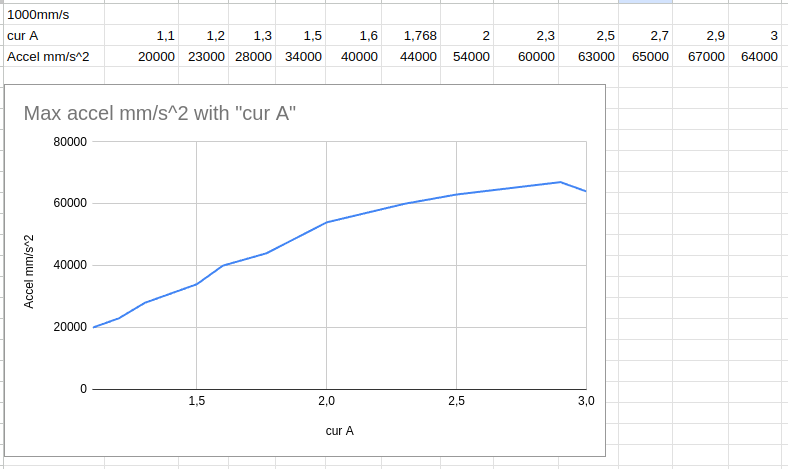

I tried both 36V and 24V, different microstepping levels, interpolation on-off, different currents, but nothing seems to fix the issue, so i guess I should start messing with the tuning parameters of the drivers.

Do you have a clue of which of the parameters listed in the reference for TMC5160 drivers could help to fix this issue?

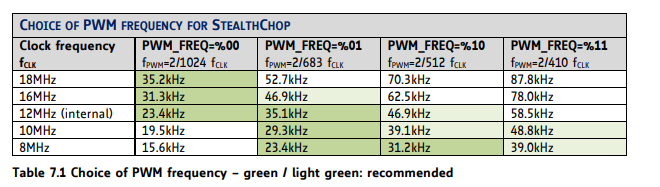

I tried taking a look at the spreadsheet provided by the manufacturer, that should guide the choice of parameters, but changing driver_TBL, driver_TOFF, driver_HEND and driver_HSTRT with the suggested values didn’t bring much improvement if at all.

Did anyone face the same issue and find a solution?

ps: I can’t povide a config at the moment as I don’t have the machine at home, but I will upload it later if necessary.

Thank you ![]()