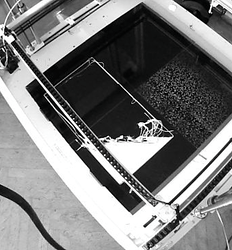

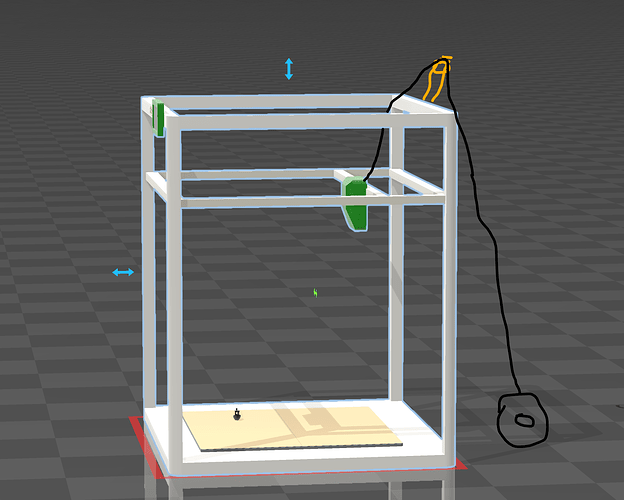

Printer Model: Elegoo Orange Storm Giga

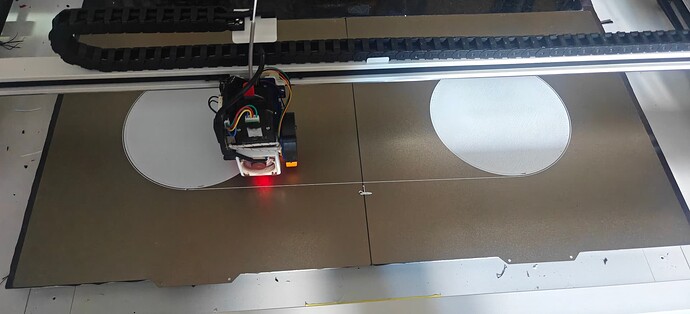

MCU / Printerboard: BTT Manta M8P, printhead: BTT EBB SB2209 CAN V1.0

Host / SBC: BTT CB1

klippy (9).log (7.2 MB)

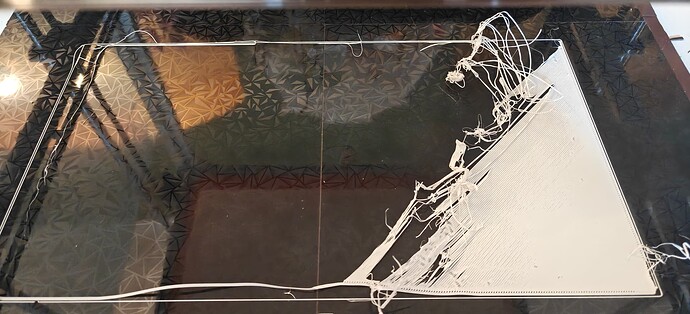

I’m having issues getting the printer to print the first layer properly. I’m currently using the BTT Eddy cartographer probe, but the same issue happened with the original probe (inductive), which leads me to believe it’s not a probe issue, but rather something else.

The print starts usually off good, but half way through, it seems to fail every time. I have tried to adjust the parameters in [bed_mesh], but nothing seems to work. Added mesh_pps, added move_check_distance, changed bicubic_tension, but the result is always the same.

This is the configuration I tried last:

[bed_mesh]

horizontal_move_z: 2.0

speed: 200

zero_reference_position: 650, 200

mesh_min:15,15

mesh_max:770,735

probe_count: 15 , 15

algorithm: bicubic

mesh_pps: 4 , 4

bicubic_tension:0.5

fade_start: 1.0

fade_end: 30.0

move_check_distance: 5

split_delta_z: .025

scan_overshoot: 9

faulty_region_1_min: 380.0, 0.0

faulty_region_1_max: 440.0, 380.0

faulty_region_2_min: 0.0, 380.1

faulty_region_2_max: 800.0, 440.0

faulty_region_3_min: 380.0, 440.1

faulty_region_3_max: 440.0, 800.0

I was wondering if this could an issue caused by the very large print area, which consists of 4 beds and is 800x800mm in total. Might be that move_check_distance isn’t working as intended on such large print areas.

Due to the large and separate beds, it’s quite hard to level them in such a way, that they’re within 0.1 - 0.2 mm, and thus the bed mesh looks quite bad. But nevertheless it should compensate somewhat for it.