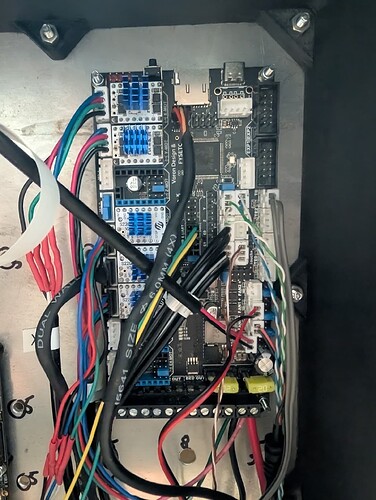

Okay, that wasn’t clear to me that the box was part of the Spider.

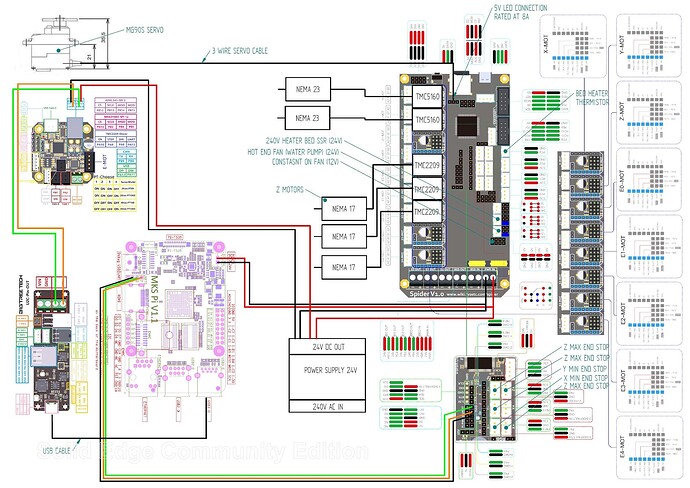

Knowing that, I have to point out that you have a ground loop between the MKS Pi V1.1 and the Spider (Ground connected on the two boards from your bulk power supply and another ground connection on the two board’s serial ports). I’m pointing that out because you’re not using shielded wires and you have some pretty long wire runs. Honestly, I would have thought that a commercially available (even from a dollar store) USB cable would be superior.

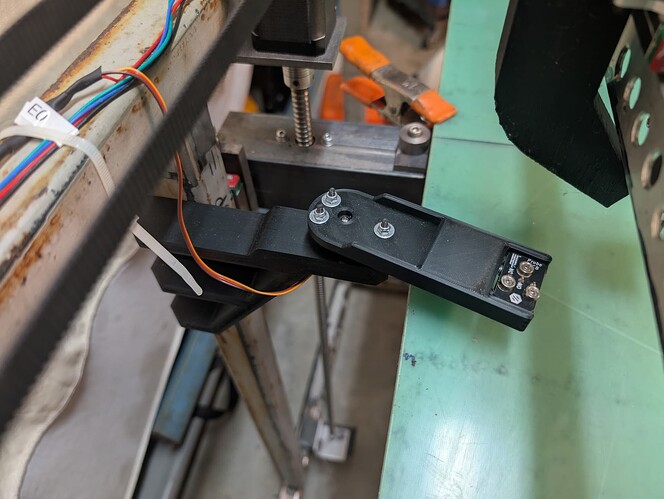

The only reason I would think that the servo could be a problem electrically is if it is stalled and even then, it will only draw 700mA:

I’m looking at the V1.1 and 5V is provided by the SY8368 Buck converter chip which is capable of 8A in normal operation and 16A for surges (I’ve used the chip in my designs) so I’m reluctant to say that in the stall condition enough current is drawn to either cause a problem with the 5V supply on the board (which also supplies the MCU) or could radiate enough energy to cause a noise problem in the system.

That’s great that the Pico is not having any issues. I hope that continues, although I would be curious as to understand what’s happening to cause the problems.

Now, if you continue to get issues, there are a few things in your klippy.log that jump out at me.

What is your printer front end? From your klippy.log, it looks like you’re running Obico and I’m wondering if there are any correlation with your problems and bringing up your front end/web page?

You have a lot of macros devoted to the servo and levelling - almost 1,500 lines worth. Who wrote them and how have you validated them on your system? I’m always suspicious of a lot of macros - there isn’t a decent debug capability available for them and they can easily run amok and do unexpected things.

Now, when I look through your macros I see that you’re setting your servo movement ranges as:

variable_servo_deploy = 172

variable_servo_retract = 50

but, as I go through your error listing, I see:

Dumping 20 requests for client 281472881345704

Received 90.515305: b'{"id": 281472803709168, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 91.515989: b'{"id": 281472803710848, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 92.249038: b'{"id": 281472803709672, "method": "gcode/script", "params": {"script": "SET_SERVO SERVO=klickyservo ANGLE=180"}}'

Received 92.517304: b'{"id": 281472803710232, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 93.522658: b'{"id": 281472803712752, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 94.520090: b'{"id": 281472803711240, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 95.521500: b'{"id": 281472803712808, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 96.324835: b'{"id": 281472803709448, "method": "gcode/script", "params": {"script": "SET_SERVO SERVO=klickyservo ANGLE=30"}}'

Received 96.522674: b'{"id": 281472803333064, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 97.523901: b'{"id": 281472803334296, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 98.529217: b'{"id": 281472803335304, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 99.526887: b'{"id": 281472803333624, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 99.710919: b'{"id": 281472803710120, "method": "gcode/script", "params": {"script": "SET_SERVO SERVO=klickyservo ANGLE=180"}}'

Received 100.527983: b'{"id": 281472803332504, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 101.531083: b'{"id": 281472803333624, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 102.530306: b'{"id": 281472803334744, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 103.531573: b'{"id": 281472803334408, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 104.535033: b'{"id": 281472803332840, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

Received 105.347303: b'{"id": 281472803334240, "method": "gcode/script", "params": {"script": "SET_SERVO SERVO=klickyservo ANGLE=30"}}'

Received 105.538405: b'{"id": 281472803332504, "method": "objects/query", "params": {"objects": {"webhooks": null, "print_stats": null, "virtual_sdcard": null, "display_status": null, "heaters": null, "toolhead": null, "extruder": null, "gcode_move": null, "gcode_macro _OBICO_LAYER_CHANGE": null, "fan": null, "heater_bed": null}}}'

I’m obviously not familiar with your code, but with a cursory look, I can’t find anywhere where the servo should be set to 180° or 30°.

Do you have any ideas on this?

Finally, when I run @Sineos 'klippy.log` analyzer, I was surprised by your bed temperature:

While the extruder maintains an even 30.3C, your bed temperature starts at 0C and then falls to almost -110C and then stabilizes at -79.7C.

I’m not sure what to make of this as I would think this means there is a problem with the thermistor connection and Klipper should catch that before moving forward. I don’t know if that is suppressed by the macros - do you have any idea?

As I said above, I hope you’ve solved your problems and let us know how things are working for you!