Basic Information:

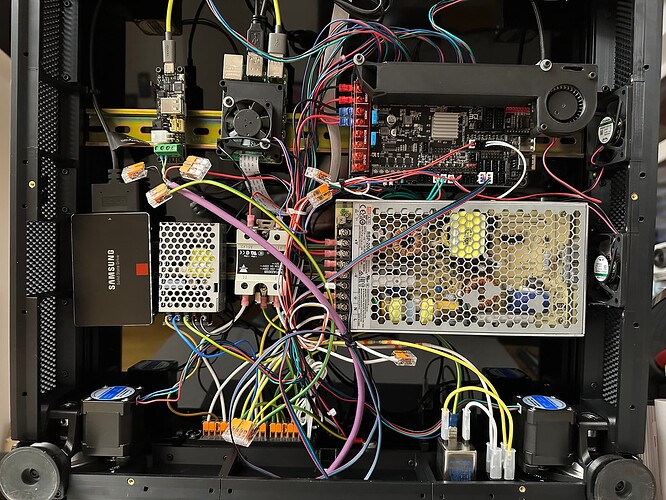

Printer Model: Voron 2.4 350

MCU / Printerboard: BTT Octopus

Host / SBC: Raspberry Pi 4B

klippy.log

Hello everyone,

I’ve been having issues with my Voron 2.4 for a while now. It keeps losing connection to my toolhead board (EBB36), which runs over CAN bus. Currently, the print fails after a maximum of 10 minutes. However, I was recently able to complete a 2-hour print.

Setup:

Voron 2.4 350

BTT Octopus → Raspberry Pi 4B → EBB U2C → EBB36 → Cartographer3D

Extruder stepper is connected via the EBB36

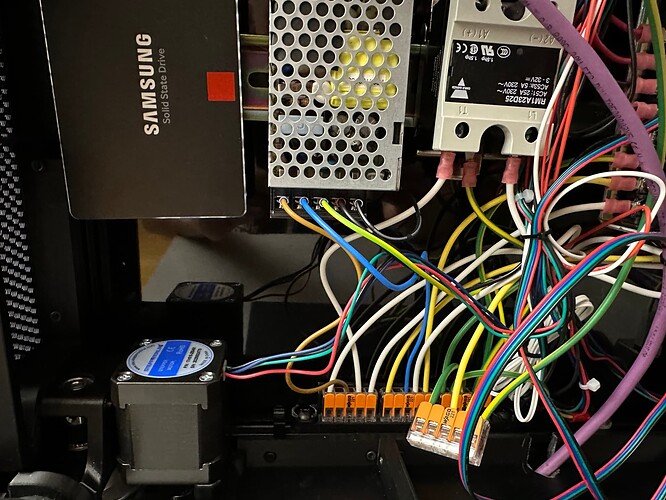

CAN cable: Igus Chainflex CFBUS.066 with shielding grounded

One Meanwell PSU for 5V (for the Pi) and one for 24V

Graphite Bed with 750W AC Heater (grounded as well)

What I’ve already tried:

- New U2C

- New EBB36 toolhead board

- New umbilical cable

- New USB cables

- Grounding the extruder stepper

- Printing without heated Bed

The only thing I haven’t replaced yet is the Cartographer. But according to the Klippy log, the printer loses connection to the EBB36. Just before the disconnect, the retransmits to the EBB36 increase significantly.

As seen in the Klippy log, the bandwidth is often at 100%. I unfortunately can’t figure out why.

My CAN bus configuration follows the Esoterical CAN bus guide:

- Baud rate: 1M

- txqueuelen: 128

At this point, I’m starting to doubt it’s a hardware issue. Possibly something else?

What I still want to test:

- Lowering the baud rate to 500k (according to research, 1M is more prone to interference)

- Replacing the Cartographer3D

- EMC (bed, heater, …)

- Firmware versions

Attached are some Klippy logs and my configuration.

Any ideas are welcome. I’m running out of options and seriously considering ditching CAN bus…

Best regards,

Andreas

printer.cfg (25.0 KB)

canbus.cfg (2.4 KB)

Unfortunatly i can only add 2 attachments… I will ad the Klippy logs later