Basic Information:

Printer Model: RepRap Anet A8 based

MCU / Printerboard: Arduino Mega

klippy.log

klippy.zip (1.7 MB)

Fill out above information and in all cases attach your klippy.log file (use zip to compress it, if too big). Pasting your printer.cfg is not needed

Be sure to check our “Knowledge Base” Category first. Most relevant items, e.g. error messages, are covered there

Describe your issue:

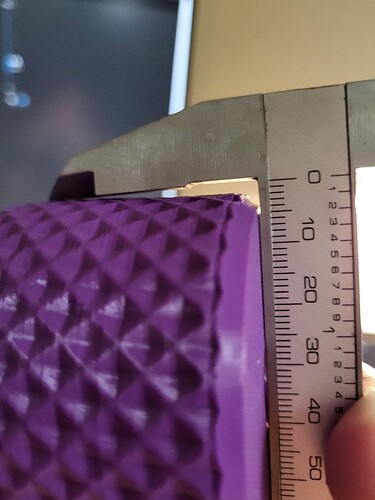

Hi, I noticed this weird problem with my printer/setup after installing BLTouch. Basically my prints started to have some kind of layer shift or something like that.

Let’s assume that I want to print perfectly straight part, something like calibration cube, but my print actually looks more like that

Red line is showing how it looks in real life.

I really don’t know what might be the cause of this issue, I noticed it after installing BLTouch, but I don’t know if this is somehow connected or unusual coincidence.

This layer shift happens only in X axis. Y is perfectly straight. I checked for loose belts or loose sprockets on steppers, but they are fine.

This is my printer.cfg

[include mainsail.cfg]

# Printer Kinematics

[mcu]

serial: /dev/serial/by-id/usb-1a86_USB2.0-Serial-if00-port0

# See docs/Config_Reference.md for a description of parameters.

[stepper_x]

step_pin: PF0

dir_pin: PF1

enable_pin: !PD7

microsteps: 32

rotation_distance: 40

endstop_pin: ^PE5

#endstop_pin: ^PE4

position_endstop: 0

position_max: 214

homing_speed: 50

[stepper_y]

step_pin: PF6

dir_pin: !PF7 # Changed from !PF7 to PF7

enable_pin: !PF2

microsteps: 32

rotation_distance: 40

endstop_pin: ^PJ1

# endstop_pin: ^PJ0

position_endstop: 214

position_max: 214

homing_speed: 50

[stepper_z]

step_pin: PL3

dir_pin: PL1

enable_pin: !PK0

microsteps: 32

rotation_distance: 8

endstop_pin: probe:z_virtual_endstop

position_max: 150

[extruder]

step_pin: PA4

dir_pin: PA6

enable_pin: !PA2

microsteps: 32

rotation_distance: 33.500

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PB4

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PK5

#control: pid

#pid_Kp: 22.2

#pid_Ki: 1.08

#pid_Kd: 114

min_temp: 0

max_temp: 250

pressure_advance = 0.125

[heater_bed]

heater_pin: PH5

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PK6

#control: pid

min_temp: 0

max_temp: 130

#pid_Kp: 45

#pid_Ki: 2

#pid_Kd: 290

[fan]

pin: PH6

[printer]

kinematics: cartesian

max_velocity: 200

max_accel: 1500

max_accel_to_decel: 600

max_z_velocity: 5

max_z_accel: 20

square_corner_velocity: 2.0

[bed_screws]

screw1: 30, 30

screw2: 30, 184

screw3: 184, 30

screw4: 184, 184

[bltouch]

sensor_pin: ^PD2

control_pin: PB5

x_offset: -23.5

y_offset: 1.0

#z_offset: 5

[safe_z_home]

home_xy_position: 125, 125

speed: 50

z_hop: 10

z_hop_speed: 2

[bed_mesh]

speed: 150

horizontal_move_z: 8

mesh_min: 35, 35

mesh_max: 180, 180

probe_count: 6, 6

mesh_pps: 3, 3

algorithm: bicubic

fade_start: 1

fade_end: 10

fade_target: 0

[neopixel leds]

pin: PH3

chain_count: 29

color_order: GRB

# Common EXP1 / EXP2 (display) pins

[board_pins]

aliases:

# Common EXP1 header found on many "all-in-one" ramps clones

EXP1_1=PC0, EXP1_3=PH0, EXP1_5=PA1, EXP1_7=PA5, EXP1_9=<GND>,

EXP1_2=PC2, EXP1_4=PH1, EXP1_6=PA3, EXP1_8=PA7, EXP1_10=<5V>,

# EXP2 header

EXP2_1=PB3, EXP2_3=PC6, EXP2_5=PC4, EXP2_7=PL0, EXP2_9=<GND>,

EXP2_2=PB1, EXP2_4=PB0, EXP2_6=PB2, EXP2_8=PG0, EXP2_10=<RST>

# Pins EXP2_1, EXP2_6, EXP2_2 are also MISO, MOSI, SCK of bus "spi"

# Note, some boards wire: EXP2_8=<RST>, EXP2_10=PG0

# See the sample-lcd.cfg file for definitions of common LCD displays.

[gcode_macro SET_ACTIVE_SPOOL]

gcode:

{% if params.ID %}

{% set id = params.ID|int %}

{action_call_remote_method(

"spoolman_set_active_spool",

spool_id=id

)}

{% else %}

{action_respond_info("Parameter 'ID' is required")}

{% endif %}

[gcode_macro CLEAR_ACTIVE_SPOOL]

gcode:

{action_call_remote_method(

"spoolman_set_active_spool",

spool_id=None

)}

[gcode_macro LEDS_ON]

gcode:

SET_LED LED=leds RED=0.25 BLUE=0.25 GREEN=0.25 TRANSMIT=1

[gcode_macro LEDS_OFF]

gcode:

SET_LED LED=leds RED=0 BLUE=0 GREEN=0 TRANSMIT=1

#*# <---------------------- SAVE_CONFIG ---------------------->

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [extruder]

#*# control = pid

#*# pid_kp = 32.579

#*# pid_ki = 2.858

#*# pid_kd = 92.850

#*#

#*# [heater_bed]

#*# control = pid

#*# pid_kp = 59.920

#*# pid_ki = 0.658

#*# pid_kd = 1363.929

#*#

#*# [bltouch]

#*# z_offset = 1.140

Yes I know that my printer is very, very old, but somehow I like to repair it every week ![]()